Insulation plays a pivotal role in residential construction, affecting a building’s energy efficiency, safety, comfort, and environmental impact. The debate between Halo Exterra by Logix Brands and Comfortboard 80 by Rockwool (Figure 1) has stirred interest among architects, contractors, and homeowners. Both are renowned for their respective qualities, yet understanding their nuances is important for informed decision-making.

Figure 1: Halo Exterra by Logix Brands and Comfortboard 80 by Rockwool

Thermal Resistance

Both the graphite polystyrene (GPS) used in Halo Exterra and the mineral wool insulation used in Comfortboard 80 achieve their thermal resistance by trapping tiny pockets of air. This trapped air acts as a barrier against the transfer of heat by conduction. The thermal resistance, measured in R-values (imperial) or RSI (metric), demonstrates the materials insulating capacity. Halo Exterra boasts a commendable R-5 (RSI 0.88) at 1.06” (26.92mm) in thickness, competing with the thermal resistance provided by Comfortboard 80 of R4.2 (RSI 0.74) per inch (25mm). While both insulation boards offer efficient insulation to maintain desired temperatures within structures, the advantage here goes to Halo Exterra.

Environmental Impact: Manufacturing

The environmental footprint of insulation materials is a key consideration and one that is gaining more and more attention from architects, contractors, and homeowners. Looking at each products Environmental Product Declaration (EPD) provides a clear picture of the impacts during manufacturing to the environment. While Comfortboard 80 uses less energy during manufacturing (44.65MJ vs 50.69 – 64.81MJ) it consumes more fresh water during manufacturing (0.0144 m3 vs 0.00649 – 0.00831m3). The total global warming potential of the two products is equivalent at 1.89 – 2.40kgCo2-eq. for Halo Exterra and 1.96kgCo2-eq. for Comfortboard 80. Let’s call this round a draw.

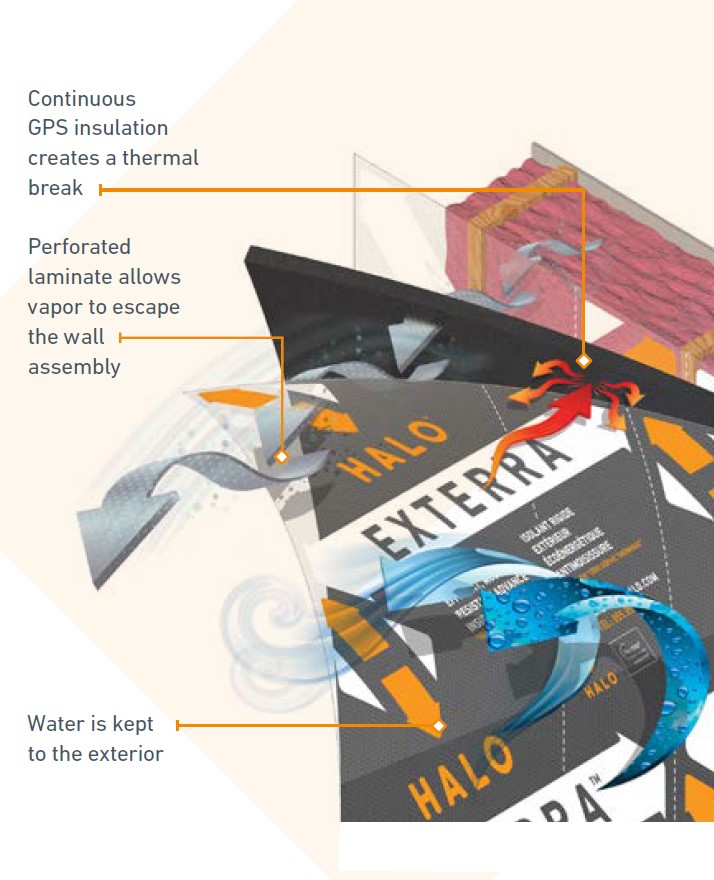

Weather Resistive Barrier: Moisture Control

When the seams and fastener penetrations of Halo Exterra are sealed with a tape or liquid applied sealant, the foam board qualifies to be used as a weather resistive barrier as per the requirements of ASTM E331. A membrane behind or in front of Halo Exterra is not required, however, it can be applied for additional protection if desired. Due to the material properties of Comfortboard 80 a membrane must be applied in-behind the insulation, which yields an additional cost for the building. Another advantage for Halo Exterra.

Water Vapor Permeance: Moisture Control

There’s no question Comfortboard 80 has a higher vapor permeance than Halo Exterra. This means there is the opportunity for more, or at a higher rate, of moisture escaping the assembly via vapor diffusion compared to Halo Exterra. To help improve Halo Exterra’s performance in allowing moisture to escape the assembly via vapor diffusion the polypropylene facer features tiny perforations. This increases the vapor permeance allowing more moisture to escape. Logix Brands would also recommend the use of a variable vapor permeance retarder on the interior of the wall assembly to further enhance the drying potential allowing controlled moisture movement and safeguarding against issues like mold or decay. The advantage of this category goes to Comfortboard 80.

Combustible vs. Non-Combustible

The National Building Code of Canada and the International Residential Code in the United States of American both clearly define the requirements for a products categorization of combustible or non-combustible. According to the testing standards within the respective building codes Comfortboard 80 is classified as non-combustible, while Halo Exterra is noted as a combustible building material. Even though the product is classified as combustible, it has been safely used on projects throughout North American and both building codes permit it’s use on residential construction projects. The verdict, minor advantage to Comfortboard 80 dependant on the building configuration.

Conclusion: Making an Informed Choice

In the decision between Halo Exterra and Comfortboard 80, the choice ultimately hinges on project specifics and priorities. Halo Exterra impresses with its thermal resistance, yields lower construction costs, and represents a sustainable building material choice, while Comfortboard 80 excels in it’s classification of non-combustible. Architects, contractors, and homeowners should assess these factors against their project needs for optimal decision-making.