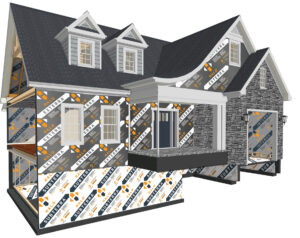

Exterior continuous insulation such as Halo Exterra has become a minimum requirement in building codes across most of North America for residential buildings.

At the initial stages of exterior insulation, the thickness applied ranges from ½ an inch (13mm) up to 2 inches (50mm) depending on the climatic zone. As building codes progress towards more energy-efficient buildings the amount of exterior continuous insulation will certainly increase as it represents an effective and efficient means to reduce the energy consumption of a building.

When working with Halo Exterra greater than 2 inches (50mm) of thickness, what are the options for fastening?

Securing exterior insulation beyond 2 inches (50mm) in thickness can be divided into two categories, plain board attachment and attachment with a furring strip.

Plain board attachment is the fastening of the exterior insulation independent of the cladding attachment. Often a minimum number of fasteners are specified by the manufacturer per sheet of insulation with a minimum requirement for penetration depth into the substrate, diameter of the washer, and fastener diameter. For more information on these fastening recommendations for Exterra, read this article.

For applications into a wood substrate (sheathing or stud) the fastener is often a plastic washer and a screw as noted in Figure 1. The screw length can be adjusted to accommodate any thickness of exterior insulation. In a plain board attachment system often, the cladding installed overtop of the insulation is brick, stone, EIFS, or stucco.

The second securement option lends itself to siding (vinyl, composite, cement…etc.) as the cladding. It consists of an untreated (typically) or treated wood furring strip installed on the front face of the exterior insulation.

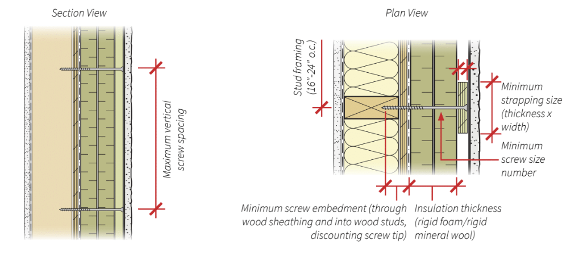

The furring strip is fastened with a screw through the insulation to either the structural wood sheathing or stud. The cladding would then be secured to the furring strips with a separate fastener. Horizontal claddings will require vertical furring strips, while vertical or panel claddings often require horizontal furring strips.

When horizontal furring strips are required, it is recommended to first install a layer of vertical furring strips followed by a second layer of horizontal furring strips. This approach ensures drainage and ventilation are maintained behind the cladding. To facilitate exterior insulation installation, a plain board attachment fastener could be used or an adhesive, which functions as a temporary hold until the furring strips are secured overtop of the insulation. The temporary attachment method only needs to be sufficient to hold the exterior insulation in place during construction.

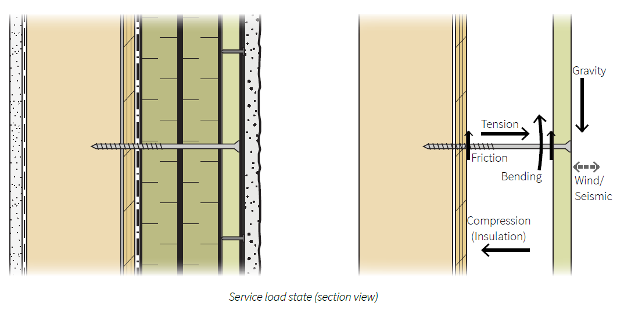

The primary concern when fastening a thick layer or layers of exterior insulation revolves around the potential for long-term creep (movement due to loading) of the fastener. Figure 2 highlights the various structural loads the fastener is under in this application.

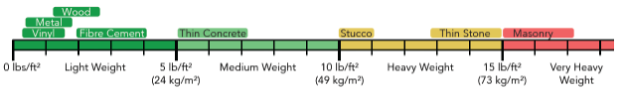

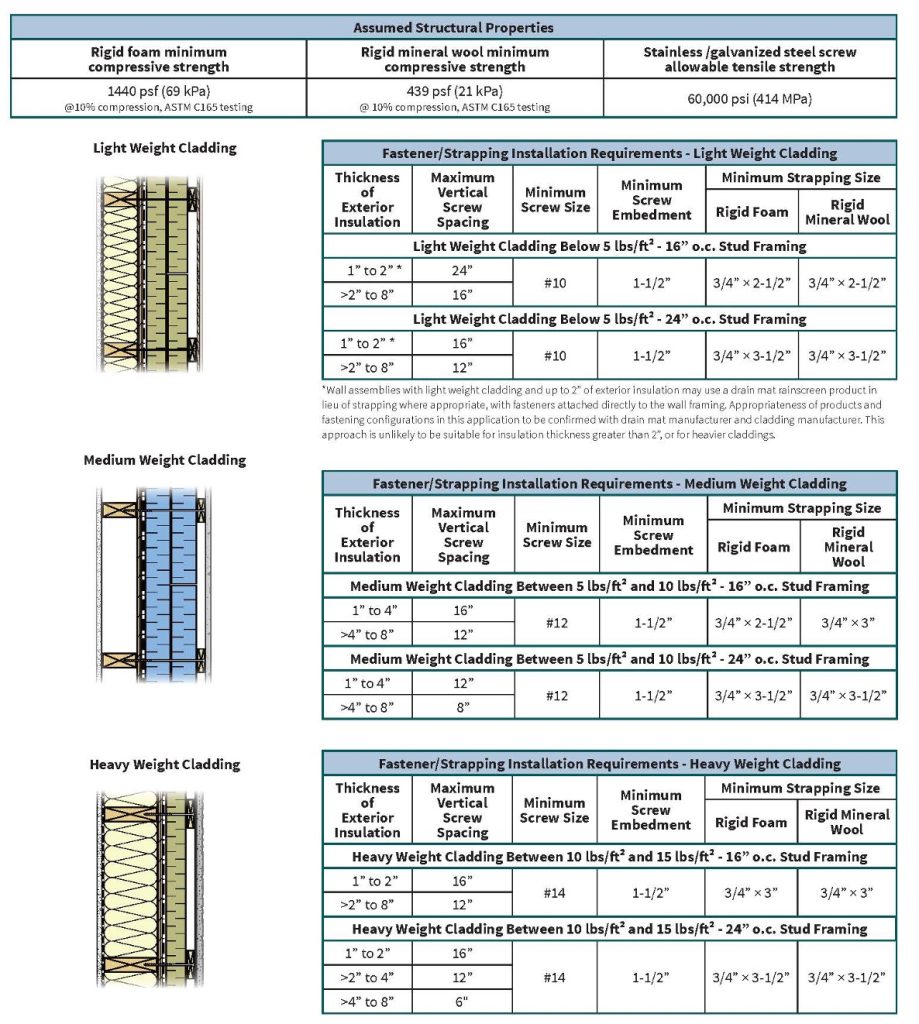

The potential for movement of the fastener depends on the weight of the cladding which has been verified by various research reports (Figure 3).

Lightweight cladding, which is typically defined from 0 lbs/ft2 to 5 lbs/ft2 (24 kg/m2), to-date has presented no known problems. Medium weight claddings 5 lbs/ft2 (24 kg/m2) to 10 lbs/ft2 (49 kg/m2) have also performed well, while little to no problems reported.

Moving into heavy weight cladding 10 lbs/ft2 (49 kg/m2) to 15 lbs/ft2 (73 kg/m2) and very heavy weight claddings greater than 15 lbs/ft2 (73 kg/m2) caution should be applied to the maximum thickness of the exterior insulation and often an engineer should be consulted.

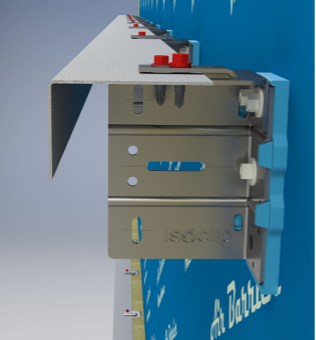

In some applications a thermally broken clip may be required that is secured directly to the stud through the structural sheathing (Figure 4). In this application exterior insulation can then be placed around the clips and the cladding can be secured to horizontal or vertical rails that connect to the thermally broken clips.

There are several residential cladding guides available to help guide industry stakeholders in securing exterior insulation that is greater than 2” (50mm) in thickness.

Figure 5 features the fastener table from the R22+ Effective Walls in Residential Construction in British Columbia Illustrated Guide. Depending on the weight of the cladding and the insulation thickness the table will provide:

- Maximum vertical screw spacing

- Minimum screw size

- Minimum screw embedment

- Minimum furring strip size

It’s important to note the values provided in these design tables typically pertain to low-rise wood-frame wall assemblies that have a building height of three stories or less.

There’s no need to fear the securement of an exterior insulation such as Halo Exterra which is greater than 2” (50mm). There are several resources available, and it often comes down to the use of a longer screw with a washer or furring strip.

Don't miss a thing!

Subscribe for exclusive content, insider industry news and limited edition webcasts.