Are you thinking about renovating your ceiling or interior walls? Slapping on a fresh new finish is a noticeable improvement, but have you thought about improving your walls’ thermal performance and slashing energy use?

The case study below will dissect a recent project where Halo’s Interra panels played a crucial role in boosting a home’s energy efficiency and making installation that much more straightforward.

Jay Mincho’s Cabin — A Case Study

Jay Mincho’s cabin is perched on the shores of Lake Manitoba in Steeprock, MB. The 1,030 ft2, 2-bedroom, 2-bathroom cabin with cathedral ceilings was a new build — but we’ll profile it here because the same Interra application easily applies to renovations.

Simplify Insulation For Challenging Wall Assemblies

For his project, Jay Minho chose to insulate the cabin’s expansive cathedral ceilings with Halo’s Interra. He used the same product under the loft’s flat ceilings and in the feature prow wall.

And for a good reason — Interra panels come with an integral vapor barrier. And of course, it’s much simpler to fasten 4’ x 8’ rigid boards to sloping surfaces than to cover these surfaces with rolls of poly — all while working from a 13-foot tall scaffolding.

Jay is also happy with the other great benefit he got — Interra also added crucial thermal resistance to the cabin’s prow wall.

Add R-Value and Eliminate Thermal Bridging

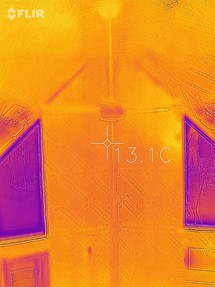

The feature prow wall’s studs created massive amounts of thermal bridging, so Jay created a powerful, airtight thermal break by applying another layer of continuous insulation (Interra) on the inside and beefing up the wall assembly’s R-Values. Here’s an infrared photo illustrating just how much of a difference this layer of Interra made in thermal bridging. These shots were taken with an outdoor temperature of about 0°C, and roughly 12°C inside.

Remember to Seal the Edges!

To ensure that his Interra approach met the local code vapor barrier requirements, Jay had to seal the edges with blue tuck tape (which is rated as a vapor barrier in Canada).

He also taped the ceiling perimeter and around door and window openings with 3M 3015 tape and blind-caulked the connection. At the edge where the prow wall met the ceiling, Jay lapped the Interra with the wall’s vapor barrier, then taped the connection and face-caulked it with an acoustical sealant.

Jay finished the ceiling and prow wall with 1×6 tongue-and-groove pine boards, nailed with 16-gauge 2.5-inch Brad nails.

No Need for Overkill

With all of the tricky parts covered, Jay opted not to use Interra on the regular exterior wall; a layer of Exterra on the outside and batt in the stud bays were sufficient. Likewise, Jay left his demising walls without Interra.

Cabin’s Wall Assemblies and Interra Quantities

Here’s what Jay’s finished wall assemblies ended up comprising:

Feature prow wall assembly

- 1×6 tongue-and-groove pine boards

- 1” Interra board

- 2×6 stud with R-20 fiberglass batt insulation

- 7/16” OSB sheathing

- 1 ½” Exterra board

- Vinyl siding

Ceiling assembly

- 1×6 tongue-and-groove pine boards

- 1” Interra board

- Parallel scissor truss with R-40 fiberglass batt insulation

- Air space

- ½” Plywood

- Owens Corning duration shingles

To give you an idea of how much Interra Jay needed for this project — and how much you’d need for a similar renovation — here are his quantities:

- Ceilings ~ 815ft2

- Prow wall ~ 205ft2

The material costs for Interra were relatively minimal for Jay, amounting to around 0.4% of the total construction expenses. Of course, this percentage will likely be much higher if all you’re doing is giving your walls and ceiling a facelift.

Wrapping It Up

As you can see from the case study above, insulating your wall with Halo’s Interra can offer 2 significant benefits during a renovation. It eliminates the need for a separate vapor barrier (as long as you tape the edges), making the installation process that much easier. But it also gives you a much better wall (or roof); the layer of continuous insulation adds critical R-Value to the assembly AND creates an effective thermal break.