Canada’s response to the growing climate crisis has recently zeroed in on a significant culprit — CO2 emissions produced by residential buildings. In a significant (but expected) step, the 2020 National Building Code has officially set the nation’s construction industry on the path to Net-Zero-Readiness. By the end of the next decade, all new homes should be net-zero-ready (NZR).

This post will brief you on the impending code requirements and how they will translate into the walls you erect on your construction site. We will also present a working solution to these demanding new standards — read on to find out more.

Code Changes Signal a Gradual Shift to Net-Zero-Ready

Based on a tier system, the NBC aims to help provinces gradually roll out energy standards that get progressively higher with every tier. Thus by about 2030, most provinces could be hitting Tier 5 — Net-Zero Ready.

As a builder, you’ll have to adapt to new, energy-efficient wall designs that meet the codes’ prescriptive or performance effective R-Value criteria.

How Will Net-Zero-Ready Requirements Affect Above-Grade Walls?

To achieve Net-Zero-Readiness, the home’s building enclosure and mechanical systems will need major improvements in thermal resistance and airtightness.

The effective thermal resistance requirements stand to see a significant increase from their current levels, particularly in the colder climate zones.

More likely than not, Tier 5 homes in Edmonton, Winnipeg, and other Climate Zone 7A cities will need their above-grade walls to hit approximately effective R-36. Those built in the bitterly frigid Northwest Territories, Yukon, and the northern parts of provinces may need approximately effective R-45 above and below grade.

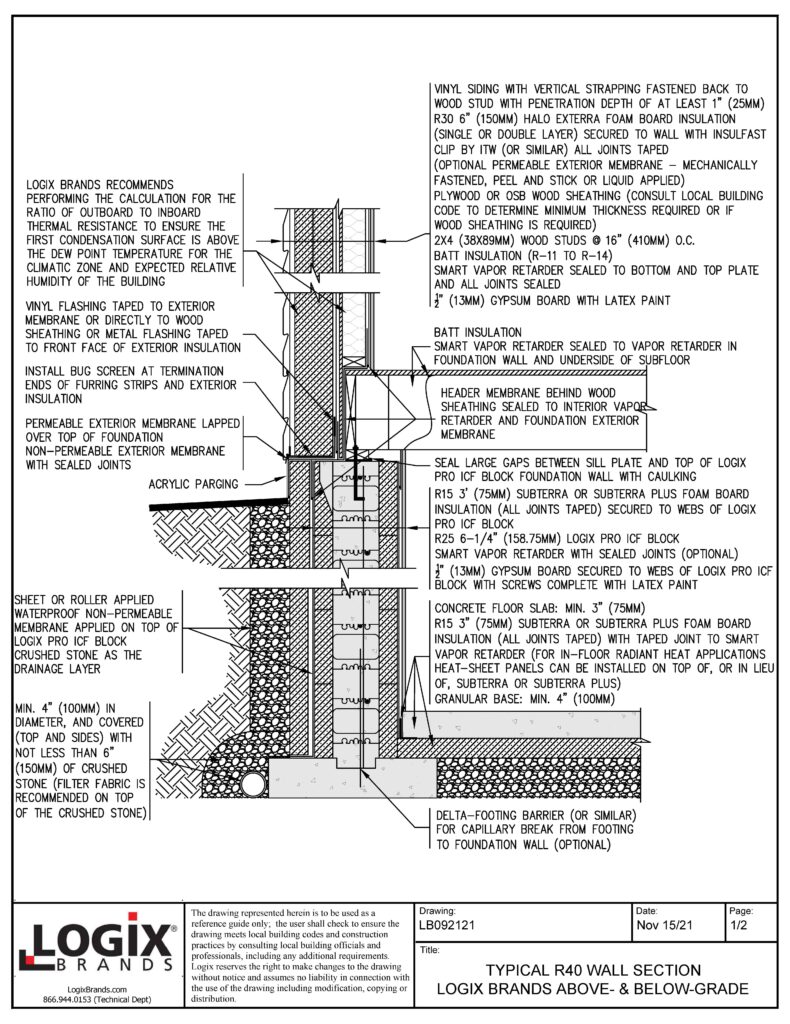

Based on these predictions, Logix Brands has designed an above-grade wall assembly to help builders like you meet (and exceed) the onerous NZR energy standards in colder climates. Here’s what it looks like.

Looking At a Net-Zero-Ready Above-Grade Wall Design

The design below is based on effective R-40, representing the average predicted R-Value requirement for northern climate zones in Canada. To minimize wall thickness, it’s based on a 2×4 stud wall, with a combination of Halo’s Exterra rigid insulation and batt in the stud bays.

The design below uses vinyl siding as the exterior finish. Along with vertical strapping, the latter is nailed to the studs. Next comes an approximately 6-inch layer of Halo’s Exterra, a vapor permeable yet water-resistive Graphite Polystyrene (GPS) board, which adds a whopping nominal R-30 to the wall. The Exterra can either comprise a single, 6-inch layer or 2, 3-inch boards. In either scenario, the foam boards get nailed to the sheathing, not the studs.

Once fastened, the Exterra panels must be taped at the joints in order to act at the weather resistive barrier (WRB); or you can also opt for a liquid-applied or peel-and-stick permeable membrane on Exterra’s exterior face, if you wish.

Beyond the Exterra, we’ve got a relatively standard stud wall. The local code adoption will determine the sheathing thickness and material, after which come the 2×4 studs, spaced at 16 inches on center. The stud bays are filled with batt, giving the assembly another R-10.

On the interior, the batt is covered with a smart vapor retarder, which is attached to the top and bottom sill plates. At the main floor joist interface, the smart vapor retarder must be attached and sealed at both the underside of the subfloor and the vapor retarder on the foundation wall (if one is used there, as it’s optional below-grade).

Finally, there’s the sheet of painted drywall enclosing the wall assembly on the interior. These elements work in concert to give a high-performance, airtight wall with a nominal effective R-value of R-40.

Note: this design needs to be calibrated on a case-by-case basis. Each climate zone’s dew point temperature and the building’s projected Relative Humidity will affect if and where condensation build-up occurs within the wall cavity. That’s why it’s essential to calculate the ratio of outboard-to-inboard thermal resistance and ensure that the wall’s first condensation surface is above the dew point temperature — this will help keep the assembly moisture-free.

Wrapping It Up

Canada’s Net-Zero-Ready standards are ambitious, particularly in colder climate zones where the required R-values will hover around the effective R-40 mark.

But as you can see with this wall assembly design, they don’t have to be rocket science — common sense high performance can be achieved by using readily available components.

Strategic Placement of House Wrap with Halo’s Exterra for Enhanced Building Protection

In 2024, optimizing your home’s insulation and moisture barrier strategies remains crucial, particularly when considering Halo’s Exterra as a pivotal component of your construction approach.

Comparing Halo Exterra by Logix Brands and Comfortboard 80 by Rockwool

Insulation plays a pivotal role in residential construction, affecting a building’s energy efficiency, safety, comfort, and environmental impact. The debate between Halo Exterra by Logix

Revolutionizing Basement Renovations: A Comprehensive Guide to Insulating and Flooring Your Existing Concrete Slab with Halo Interra

Transforming your basement is not just a home improvement project; it’s an investment in your property’s value and functionality. This guide focuses on basement finishing,