As more and more energy codes across North America require continuous insulation (CI) in wall assemblies, you may wonder — what’s the big deal with adding an R-5 foam board panel to a wall? How much of a difference can it make, energy-wise?

Turns out, adding a layer of R-5 CI to a wall is a huge deal. And the potential energy savings can be between 20-40%.

Intrigued? Read on and learn about recent tests that revealed this incredible potential for savings, all made possible by a thin, R-5 layer of CI.

Testing the Effects of Continuous Insulation on a Wall’s Energy Performance

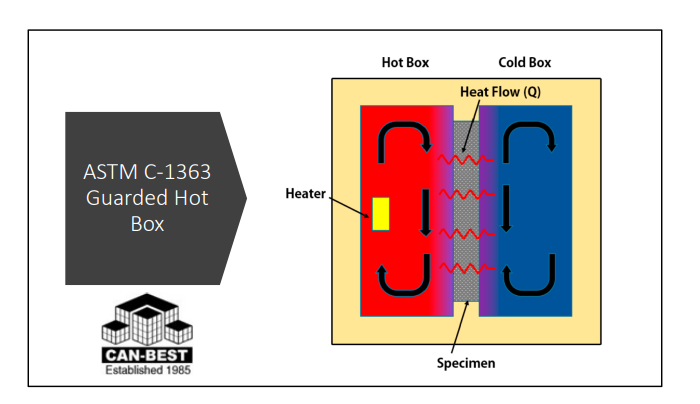

Guarded Hot-Box Test

To compare the energy performance of different wall types, the Insulating Concrete Forms Manufacturers Association (ICFMA) commissioned Cleb Laboratories to run a guarded hot-box test on several assembly samples.

This standard ASTM C-1363 test measured energy flow across the test samples, which were used to separate the hot and cold chambers. During the procedure, the warm side is maintained at 70F. When the test begins the cold side is dropped to -30F.Then, the lab team records how much heat flows through each of the wall assemblies that are being tested.

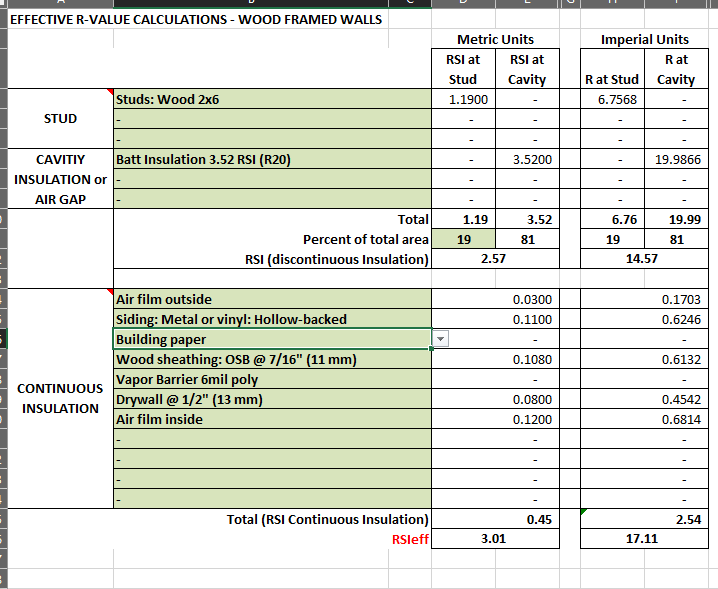

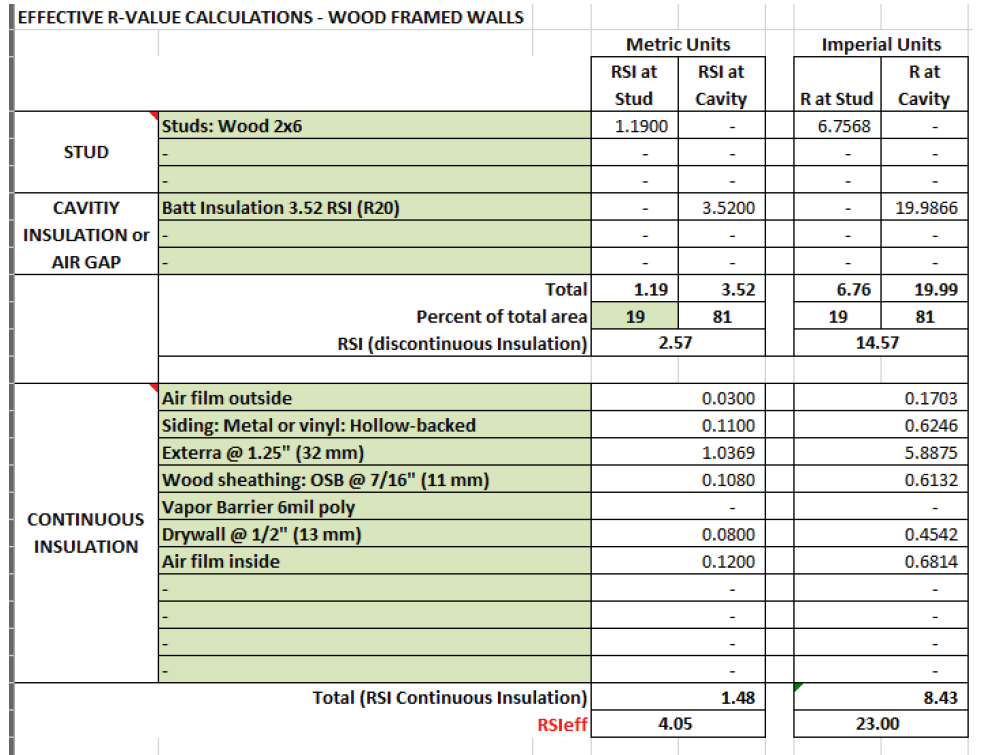

Two of these samples included a simple, R-20 wood-framed wall and the exact same wall but with a layer of R-5 CI, like Halo’s Exterra. The effective R-Values of the complete assemblies were R-17 and R-23, respectively.

Don't miss a thing!

Subscribe for exclusive content, insider industry news and limited edition webcasts.

Reaching the Equilibrium

The most crucial — and telling — part of the hot-box test is when the test sample reaches a “steady-state,” or “equilibrium.”

At equilibrium, the rate of heat flow through the wall assembly becomes constant and unchanging, and it is at that point a wall system’s “effective thermal performance” is determined.

Up until the point the state of equilibrium is reached, the rate of heat flow is ever-increasing.

Why does equilibrium matter?

Because the longer a wall takes to reach equilibrium, the more time it’s actual thermal performance is higher than its measured effective thermal performance, saving its owners precious money and reducing CO2 emissions.

How The Samples Fared

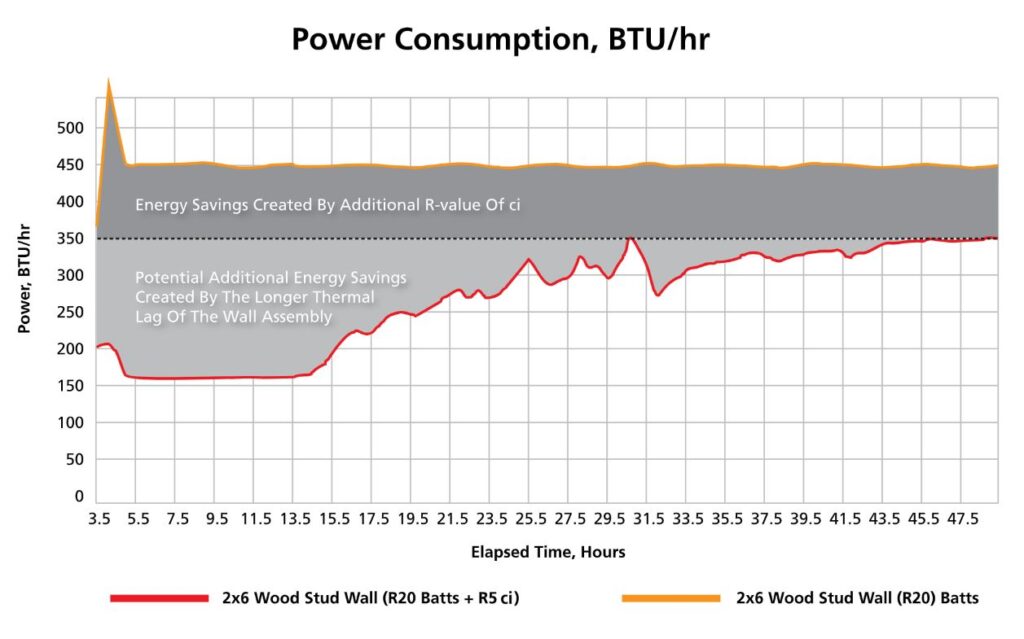

The wall assembly sample with a layer of CI performed exponentially better.

Where the standard wall assembly hit its equilibrium just over 4 hours into the test, its peer with the CI lasted a whopping 45 hours before reaching a steady-state!

In this laboratory test:

- After hitting equilibrium, the sample with the layer of R-5 CI used 23% less energy than the standard R-20 stud wall.

- Throughout the entire 55-hour test, the wall assembly with the CI layer consumed roughly 45% less energy than the R-20 wall

Those are impressive energy savings, especially considering the low cost of adding CI to a wall assembly.

These results are notable during swing seasons, when nighttime temperatures sink significantly, thus triggering the heating systems until the daytime highs return.

With a simple layer of R-5 CI like Halo’s Exterra, an overnight dip in temperatures may not even trigger the furnace or boiler to come online.

Wrapping It Up

Adding a layer of R-5 CI to a wall assembly may not seem like a significant upgrade, but the tests prove otherwise — it’s highly consequential.

The thermal resistance boost of only R-5 is disproportionately small considering the potential 20-40% in energy savings it can yield.

Given the low cost and high ROI of this upgrade, why not go for it and boost your homes’ energy performance?