Reducing Overkill Amid Unpredictable OSB Prices

In construction, being efficient pays and thus many builders typically deliver exactly to the prevailing building codes. When it comes to lateral bracing, though, they tend to go above and beyond. As a result, it’s become common practice in many regions to sheathe an entire wall with OSB even when the codes often only require bracing at the corners and certain sections of the wall to provide the needed resistance to wind and seismic loads.

With volatile and recently rising prices, however, the practice of continuous OSB layers may becoming an expensive overkill. This post will examine 2 compliant approaches that see bracing only at corners and intermittent segments of the braced wall, with continuous insulation in between.

Lateral Bracing Methods

There are plenty of lateral bracing methods out there, and their prevalence may vary by region. Locales with a risk of high winds and seismic activity – California, Oregon, Washington, British Columbia, to name a few – typically have more demanding requirements. Regions where earthquakes and wind are less prevalent, on the other hand, often allow less rigorous methods, such as let-in bracing.

In many jurisdictions braced wall panels are gaining in popularity as they let project teams balance costs with sound lateral resistance. Let’s have a look at 2 popular variants: wood structural sheathing, and the Zip System Sheathing.

Wood Structural Panel Sheathing

According to the National Building Code of Canada (NBCC) and the International Residential Code 2015 (IRC 2015), intermittent wood structural sheathing sections are a compliant bracing option. While both the NBCC and the IRC afford many prescriptive paths to compliance, these structural panels may be used to only brace corners and sometimes a certain percentage of the braced wall lines.

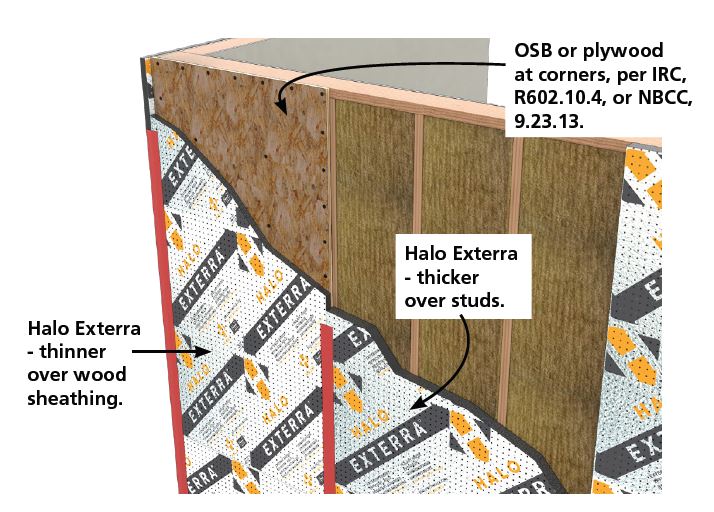

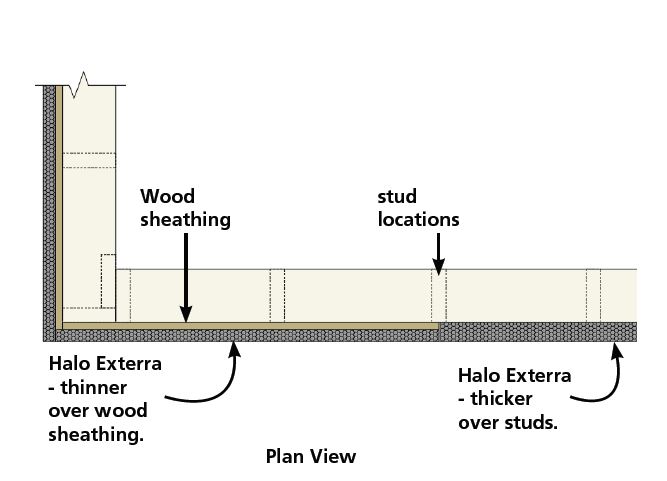

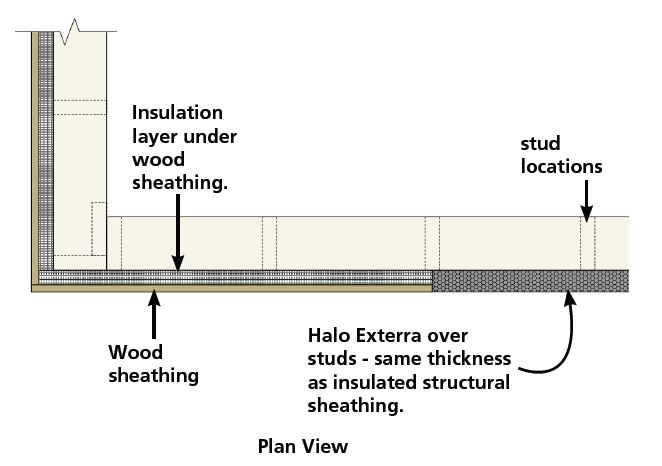

Adding shear walls to a stud assembly increases the wall depth in certain places. The framed wall gains between 3/8-inch to 1/2-inch of extra thickness at the braced corners because of the structural sheathing panels. To ensure that the insulation’s exterior face is flush along the entire wall, you must use thinner insulation panels at the braced corners than you would over the stud wall.

For the continuous insulation component, Halo® Exterra® comes in thicknesses of 0.563 and 0.625 inches. These thicknesses are perfect for accommodating the slightly thicker, braced wall sections.

Don't miss a thing!

Subscribe for exclusive content, insider industry news and limited edition webcasts.

Zip System™ Sheathing and Zip System™ R-Sheathing

The Zip System provides multifunctional benefits but works just like regular wood structural paneling in bracing the frame against lateral loads. These panels are made from laminated OSB; thanks to the laminate, the Zip System provides air and water resistance, so there’s no need for house wrap. However, you still need to insulate these panels (which are 7/16-inch thick), so the thinner 0.563-inch Exterra boards are a great option here.

Then there’s the Zip System R-Sheathing system, which combines lateral bracing and insulation into a single product. These panels usually comprise EPS foam boards bonded to the side of a laminated OSB board.

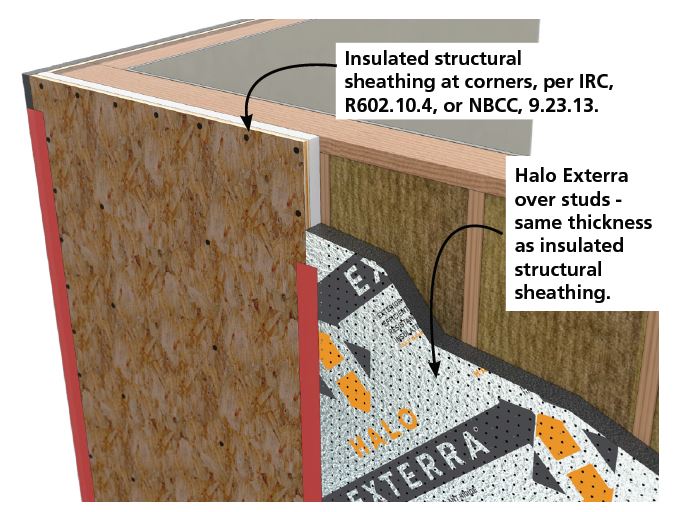

As these products use Structural-1 OSB as the bracing element, they comply with both the NBCC and IRC prescriptive requirements for lateral bracing. Much like structural wood sheathing, Zip System R-Sheathing panels can be installed only at corners and certain intervals along the wall assembly to provide the required resistance to wind and seismic loads.

You must provide insulation between sections of Zip System R-Sheathing panels and make sure the 2 components fit flush together.

Halo’s Exterra is a continuous rigid insulation that suits this application well. It comes in 3 board thicknesses that match those of the Zip System: 1.0-inch, 1.5-inch, and 2.0-inch. With corresponding dimensions, abutting Exterra boards can sit flush with the Zip System panels.

Because Exterra forms a water-resistive barrier, the entire exterior wall can be built without house wrap. What’s more, Exterra’s perforated laminate lets vapor escape the wall assembly, keeping the cavity dry.

Wrapping it Up

Structural wood sheathing and Zip System Sheathing are both code-compliant wall bracing methods. These mechanisms can be used to brace a building’s corners and a certain percentage of the braced wall line. In many regions, there is not a structural need to opt for the fully sheathed method – especially now when OSB prices are so volatile.

With Halo’s Exterra series rigid insulation, both approaches integrate perfectly into the building’s envelope.

Exterra panels work with the bracing component thicknesses to create a flush wall surface and also offer:

As a best practice, always consult the installation instructions for each building material included in your project.

Discover More With Halo

Strategic Placement of House Wrap with Halo’s Exterra for Enhanced Building Protection

In 2024, optimizing your home’s insulation and moisture barrier strategies remains crucial, particularly when considering Halo’s Exterra as a pivotal component of your construction approach.

Comparing Halo Exterra by Logix Brands and Comfortboard 80 by Rockwool

Insulation plays a pivotal role in residential construction, affecting a building’s energy efficiency, safety, comfort, and environmental impact. The debate between Halo Exterra by Logix

Revolutionizing Basement Renovations: A Comprehensive Guide to Insulating and Flooring Your Existing Concrete Slab with Halo Interra

Transforming your basement is not just a home improvement project; it’s an investment in your property’s value and functionality. This guide focuses on basement finishing,